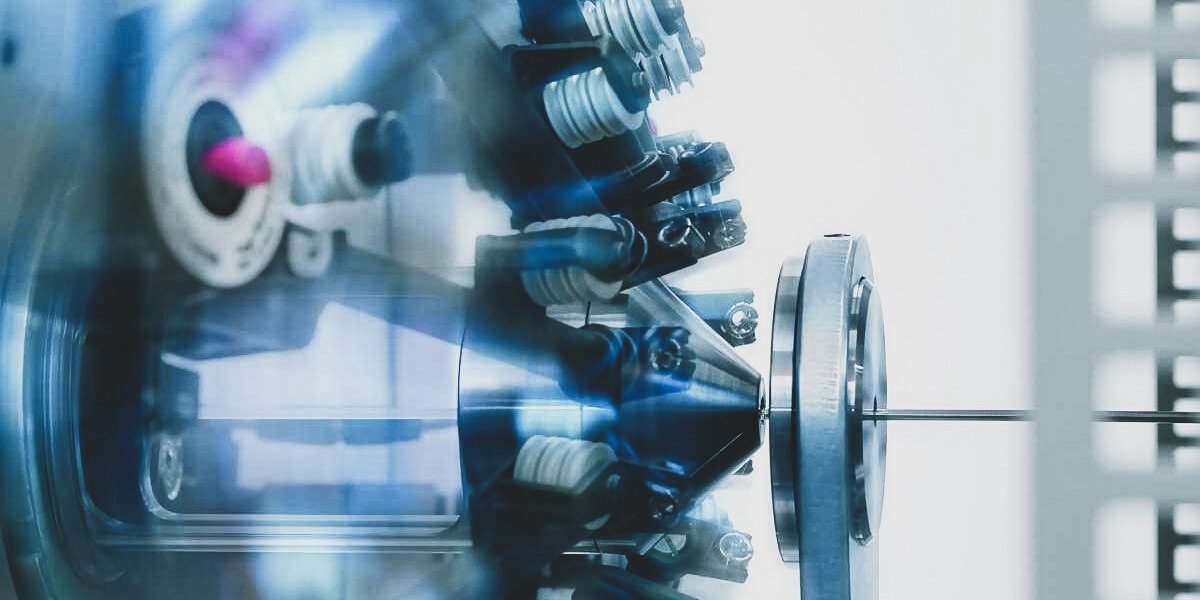

Wir entwickeln innovative, kundenspezifische Maschinenkonzepte für Flechtmaschinen auf Spitzenniveau. Wir bauen Flechtmaschinen aus Überzeugung. Dabei folgt alles einem Ziel: maximale Leistungsfähigkeit zu erreichen. Auf Qualität von Steeger können Sie sich verlassen.

Die nächste Generation von Flechtmaschinen

Steeger Flechtmaschinen sind Hightech-Produkte erster Güte, nachhaltig, energiesparend, durchdacht, mit Lebenszeiten von bis zu 30 Jahren. Jede einzelne Maschine ist eine Innovation. Wir bauen keine Maschinen von der Stange, sondern entwickeln maßgeschneiderte Unikate, die auf die spezifischen Erfordernisse der jeweiligen Branche und den entsprechenden Einsatzbereich zugeschnitten sind. Unsere Maschinen verfügen über modernste Elektronik und energieeffiziente Motoren. Dabei macht unsere Entwicklungstiefe auch vor der Erfüllung von Sonderwünschen nicht halt, ob Fernüberwachung oder digitale Zusatzfunktionen. Steeger Flechtmaschinen sind eine Investition in die Zukunft.

Jede Maschine – eine Innovation

Wir führen professionell sowohl Vormontagen als auch Endmontagen von Neumaschinen und Anlagen durch. Auch nach dem Kauf einer Maschine bieten wir Ihnen umfassenden Service. Je nach Bedarf erledigen unsere erfahrenen, weltweit einsetzbaren Teams die Arbeiten direkt bei unseren Kunden vor Ort.

Innovativ

Wir handeln und arbeiten zukunftsorientiert und versuchen, unsere technischen Möglichkeiten stets zu verbessern.

Transparent

Wir zeigen uns gegenüber den Kunden, Lieferanten und Mitarbeitern stets offen und fair.

Nachhaltig

Wir sind stets bemüht, die Umweltbelastungen so gering wie möglich zu halten.

Wuppertal war bereits Anfang des 19. Jahrhunderts eines der wichtigsten Zentren der Industrialisierung und zentraler Entwicklungsstandort für die deutsche Textilindustrie.

Unser Einfluß auf die Wuppertaler Textilgeschichte

Maßgebliches Element der Wuppertaler Textilgeschichte war die Herstellung von Bändern, die gewebt, gewirkt oder geflochten wurden. Zunächst von Hand oder auch an handbetriebenen Webstühlen, die mit der Zeit durch immer besser funktionierende Maschinen ersetzt wurden. Großen Anteil an der enormen Weiterentwicklung der textilen Flechtmaschinen am Standort Wuppertal hatte das Unternehmen Steeger, durch dessen Innovationskraft enorme Fortschritte in den gesamten Produktionsabläufen erzielt wurden.

Über 130 Jahre Wissenstransfer

Die über 130-jährige Erfahrung im Bau und der Entwicklung von Flechtmaschinen für alle flechttechnischen Belange der verschiedensten Branchen ist auch in Zukunft ein Garant für maximale Produktivität. Diesen Wurzeln sind wir bis heute treu geblieben. Der Unternehmensstandort liegt verkehrsgünstig im Bergischen Land im Städtedreieck Wuppertal, Solingen, Remscheid und ist schnell erreichbar. Dank der Nähe zum Flughafen Düsseldorf bieten sich hier optimale Bedingungen für eine weltweite Zusammenarbeit.

Weltweiter Service und Support

Neben den Montagearbeiten an Maschinen und Anlagen, nehmen wir auch Anpassungen und Reparaturen vor und stehen für Wartungsarbeiten sowie Kundendienst zur Verfügung.

Wir denken global und liefern weltweit Ersatzteile für alle Maschinen aus unserem Hause – auch für Maschinen die 40 Jahre und älter sind. Gängige Verschleißteile sind im Regelfall innerhalb von 48 Stunden lieferbar.

Sie möchten Full-Service aus einer Hand?

Wir bieten die entsprechenden Wartungsverträge.

Aus Tradition besser

Perfektion ist Stillstand.

Deshalb entwickeln wir uns und unsere Produkte immer weiter.

Unternehmensgründung

Mit der Gründung der Firma Wilhelm Körting, die sich auf den Bau von Flecht- und Zuberhörmaschinen sowie einfädige Klöppelspitzenmaschinen spezialisiert hat.

Zusammenschluss mit Steeger

Aus Wilhelm Körting wird durch den Zusammenschluss mit Wilhelm Steeger die Firma Körting GmbH. Ziel ist die Ausweitung in den internationalen Markt.

Umfirmierung unter dem heutigen Namen

Nach dem Ausscheiden von Karl Körting wird die Firma unter ihrem heutigen Namen „Körting Nachfolger Wilhelm Steeger GmbH & Co KG“ fortgeführt.

Generationsübernahme

Nach dem Tode von Wilhelm Steeger übernimmt seine Tochter Ingeborg Lange mit Ihrem Ehemann Hans-Adolf Lange die Unternehmensleitung.

Firmenübernahme

In diesem Jahr übernehmen Hans-Joachim Ludwig, Klaus-Michael Menser und Bernd Rehrmann die Unternehmensführung, die wenige Jahre später von Hans-Joachim Ludwig an dessen Sohn Axel Ludwig übergeben wurde.

International führend

Steeger Flechtmaschinen gehört zu den international führenden Unternehmen und wird durch Axel Ludwig und Bernd Rehrmann geleitet.

Ein kleiner Auszug aus unserem Flechtmaschinen Angebot.

Ein guter Ruf

verpflichtet

Was heute zählt, ist die Geschwindigkeit der Innovation, als fundamentaler Vorteil im Wettbewerb. Unaufhörlich und in immer kürzeren Abständen, wächst die Anzahl neuer Werkstoffe, die zu immer innovativeren Produkten verarbeitet werden. Um mit dieser Entwicklung Schritt zu halten, bedarf es der Fähigkeit, beständig einen Schritt weiter zu denken. Besondere Herausforderungen gehen wir in enger Kooperation mit unseren Kunden an.

Schulungen

Neue Werkstoffe und Produkte können Fragestellungen hinsichtlich der Behandlung und Verarbeitung aufwerfen. Als erfahrener Maschinenhersteller bieten wir Ihnen im Rahmen unserer professionellen Schulungen wertvolle Unterstützung bei Neuentwicklungen, Tests oder auch Nullserien zur Produkteinführung. Auch bei Fragen zum bestehenden Maschinenpark sind wir mit Rat und Tat für Sie da. Wir beraten und unterstützen Sie gerne, sowohl in Ihrem Unternehmen vor Ort als auch bei uns im Werk in Wuppertal.

Produkteinführungen

Jede einzelne unserer Hochleistungs-Flechtmaschinen ist das Ergebnis jahrzehntelanger Erfahrung und Entwicklung. Unser Produktionsprogramm ist individuell und vielseitig, stets den Erfordernissen der verschiedenen Verwendungszwecke angepasst. In der Umsetzung heißt das, wir entwickeln Ihr Produkt von den ersten Skizzen über Konzept und Kostenanalyse bis hin zur fertigen Konstruktion und Dokumentation. Jeder Schritt erfolgt in enger Abstimmung mit unseren Kunden. Wir übernehmen die Pflege Ihres Produktes mit stetigen Verbesserungen, Austausch von Verschleißteilen, Ersatzteilservice und ggf. Instandhaltungsservice.

Beratung & Konzeption

Am Anfang jeder Maschine steht die Idee. Als innovativer Maschinenbauer sehen wir es als unsere Aufgabe anhand von Produktideen Lösungen für den kompletten Produktionsablauf zu finden. Im Rahmen der Ideenfindung diskutieren wir auch mit Ihnen über „unmögliche“ Ideen und geben erst auf, wenn es wirklich nicht machbar ist.

Wir stehen unseren Kunden bei jedem Schritt zur Seite: ob bei der Planung von Produktionsabläufen, beim Festlegen von Maschinenanordnungen oder bei der Konzeption von Fabrikationsgebäuden, die später mit Maschinen bestückt werden sollen. Dabei spielen auch die technischen und ökonomischen Rahmenbedingungen eine wichtige Rolle.

Nachfertigung von Ersatzteilen

Qualitätsmaschinen von Steeger erreichen häufig eine Lebensdauer von über 30 Jahren. Auch für diese Maschinen können wir Ersatzteile nachliefern oder gezielt anfertigen. Die entsprechenden Pläne, anhand derer wir defekte Teile identifizieren und nachfertigen können, reichen weit über 50 Jahre zurück. Wenn Sie das benötigte Ersatzteil nicht genau benennen können, kontaktieren Sie uns bitte direkt über das Ersatzbestellformular. Hier können Sie auch ein Foto des benötigten Teiles hochladen. Möchten Sie eine ältere Maschine komplett überholen lassen, dann kontaktieren Sie uns bitte direkt. Gerne machen wir Ihnen ein detailliertes Angebot für eine Generalüberholung.

Kontinuierliche Innovation nach den neuesten technischen Erkenntnissen, werterhaltende Produktzuverlässigkeit und erstklassige Qualität sind die Grundlage unseres Handelns.

Produzierende Unternehmen stehen mehr denn je vor der Herausforderung, nachhaltig profitabel zu wachsen und sich im globalen Wettbewerb zu behaupten. Durch den steigenden Kostendruck, fortwährende technologische Weiterentwicklungen und sich beständig ändernde Kundenwünsche müssen Unternehmen ihre Produktionssysteme in immer kürzeren Zyklen an den Märkten ausrichten. Mit seinen anpassungsfähigen Lösungen unterstützt Steeger seine Kunden dabei, diesen Ansprüchen immer wieder gerecht zu werden.

Das Baukastensystem von Steeger

Das Baukastensystem von Steeger eröffnet optimale Voraussetzungen für die flexible Produktion von Geflechten mit verschiedensten Konfigurationen.

Medizin- und Kabeltechnik

Die Flechtmaschinen von Steeger sind seit über vier Jahrzehnten in allen Bereichen der Medizintechnik zu finden. Speziell in der Fein- und Feinstdrahtverarbeitung gehört Steeger zu den weltweit führenden Unternehmen.

Aus der Seilflechttechnik

Seilflechtmaschinen von Steeger werden in der Industrie zur Fertigung von Seilen für die verschiedensten Anwendungen eingesetzt. Ob Harnischkordeln für Webmaschinen, hochsichere Bergseile oder schwere Seile für die Offshore Industrie.

Sie haben Interesse an einem Gesprächstermin?

Lassen Sie sich von unseren Experten beraten. Wir stehen Ihnen in allen technischen Belangen zur Seite, von der ersten Idee über die Konzeption bis hin zur Endmontage Ihrer Flechtmaschine.

Steeger Flechtmaschinen

Steeger entwickelt innovative, kundenspezifische Maschinenkonzepte für Flechtmaschinen auf Spitzenniveau. Dabei folgt alles einem Ziel: maximale Leistungsfähigkeit zu erreichen durch maßgeschneiderte Maschinenkonzepte.

Kontakt

Körting Nachfolger

Wilhelm Steeger GmbH & Co. KG

Wittensteinstrasse 208 – 212

42283 Wuppertal, Germany

T + 49 202 25555 – 0

F + 49 202 25555 – 33

E info@steeger-online.de

Rechtliches

©2020 Steeger Flechtmaschinen | All rights reserved